-

Posts

393 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Events

Articles

Downloads

Gallery

Posts posted by Martin Griffith

-

-

Hi Mark,

The Strict Mode Fixed Flows option should generate warnings for any fixed flows that are adding pressure. If the fixed flow is adding resistance, it won't throw a warning. If you have pressure-adding fixed flows (the green ones) that are not generating a warning with the option on, then there is something wrong. In that case please send us the model at ventsim.support@howden.com and we will work out what is happening.

-

The spreadsheet as mentioned is very useful for this. You also have access to a Distance and time to Refuge bay colour properties which can be useful. The dark blue areas will be 0 distance, ie where your refuges are.

If you just want to find the refuge wbay, you can use the Find Select tool to cycle through them

Finally on the spreadsheet, drag the refuge bay present property to the top to group by that property, then you will a row for each refuge bay, which you can right click on to find in the viewer. You can also save spreadsheet views if this is something you want to do regularly.

-

Hi Phil, I've sent you a message through the forum's direct message service.

-

Ah thank you, I see it now. Definitely a bug, apologies for that. We will fix that in the next version. I can also send a test version to you with the fix if you like. Please let me know.

Thanks again.

-

This is now out in Ventsim DESIGN version 6.0.1.7. The new Radon Simulation method calculates correct radon progeny levels for long residence times (>70 minutes).

-

Hi Phil,

Sorry you've had this problem.

To be clear, can you please tell us which Preset you are looking at (Explosives, Combustion Fuels, Battery Combustion or Gas Mixtures) and also tell us which version of the software you are using? You can find the version number by going to Help | About on the Ventsim main window.

-

Hi Roy, as discussed via email, the calculation Ventsim is relying on to calculate this is not correct for residence times longer than about 70 minutes. Thank you for bringing this to our attention.

We've redone the calculation ourselves, so that it is correct for all residence times. This will appear in a new version soon.

-

Thanks Nathan, have found the problem here, the value is not correctly updating for changes made to diameter and density when using the Enter as Velocity. This will be fixed for the next version.

-

Hi Nathan,

This is a good location for your post.

Determining the correct area for your survey is critical and appreciate your contributions here. It's something we are dealing with often. These are the sort of things we will be considering for the next Ventlog version.

-

Hi Nathan,

As I wrote on your other post! Thank you, we have noted the requests and will look at doing this for the updated version of Ventlog planned for later in the year.

-

Hi Nathan,

Thank you for your thoughts on this. We will consider this for an updated version of Ventlog we are planning for later in the year.

-

Hi Yves,

It is hard to diagnose the problem, would you be able to send us the model? You can send it to me via the forum direct message service, or email us at ventsim.support@howden.com . Anything you send us will be treated confidentially and only used for determining this problem.

-

"Also, on the list of preset "Heat Moisture Diesel", using Craig's example above, if I put (500 kW x 0,25 = 125 kW) as the Electric Vehicle Power and 1 as the Utilisation factor, will it produce the same heat input as what is shown above (500 kW as the Electric Vehicle Power and 0.25 as the Utilisation factor)? I saw other users do this way."

Yes, that is how it works.

-

Thanks Adrian, yes, agree with your point about the lower temperature overall of the vehicle affecting the moisture production per unit of work output. Perhaps it would be more equivalent between the two types if formulated per unit of heat output, rather than work output.

We are not 100% sure at the moment so for now makes sense to retain separate settings between diesel and electric vehicles, and to keep an eye on research as it develops.

-

As discussed at the recent Ventsim User Conference, this is a developing field and the way that Ventsim handles this is not set in stone.

Thinking more on this, one possible resolution is:

==============================

Current

Water to Diesel Ratio = 6.0 litres/litres

Electric Vehicle Latent Heat Factor = 50%

================================

Proposed

Water to Diesel Ratio = 6.0 litres/litresElectric Vehicle Latent Heat Factor = 50%Water to Diesel Stoichiometric Combustion Ratio = 1.1 litres/litres

Vehicle Work Moisture Production = X (litres/s)/kW output

==============================

Both diesel and electric vehicles would use the Vehicle Work Moisture Production setting, while diesel would add 1.1 litres more water per litre of diesel used, to account for combustion. This would allow an easier comparison, and mean that you wouldn't have to do the calculation yourself that I described in the second last paragraph of my previous post.

When opening old models we could generate the new setting based on the existing water to diesel ratio setting. The old Water to Diesel ratio setting could be left there as well and changing it would recalculate the Vehicle Work Moisture Production setting.

A problem is the assumption that the non-combustion related moisture production mechanisms on the vehicles (ie the Vehicle Work Moisture Production) are the same for electric and diesel, per unit of work output done. Which they might not be if you consider that the BEV is using regenerative braking and we may have a lower utilisation factor on the BEV in our model to reflect this, which could be a factor. Not sure of the answer there, any advice or suggestions welcome!

-

The software has different settings for handling the sensible to latent ratio from diesel vehicles and BEV's and that is something we ideally should make consistent. We hear you on that, the difficulty would be to come up with a BEV equivalent of litres of water per litre of diesel. We will think more on this, it could involve changing the original diesel setting.

As is, the setting "Simulation | Heat | Water To Diesel Ratio" for diesel accounts for both the combustion products and the other associated moisture production from the machine and surrounding wet environment, as described in McPherson section 15.3.2.2. If you are operating your diesel vehicle in a very dry environment, it would stand to reason to reduce this ratio.

In your case of the BEV where you are separately modelling the moisture from the load and you seem to be operating in a very dry environment, you could reduce the setting "Simulation | Heat | Electric Vehicle Latent Heat Factor" to a lower value; reducing to zero would imply there is no moisture in the surrounding environment, nor involved in any of the other mechanical processes on the vehicle.

To do a detailed investigation and comparison in Ventsim, you could work out the water-to-diesel ratio for diesel minus the moisture from the fuel (by subtracting 1.1 litres/litre from the ratio), work out the equivalent kW of latent heat per kW of diesel power attributable to the non-fuel combustion moisture evaporation, then apply the BEV latent heat factor percentage to match this for your BEV. This should work, however, with the assumption that the non-combustion moisture production is the same between BEV's and diesel vehicles (which may not be correct because of regenerative braking).

Thanks for the link to the paper, I think the results of such work are getting out there and users are setting lower utilisation factors on BEV's than they would use on equivalent diesel machines to reflect the lower power consumption from regenerative braking.

-

It’s time for Ventsim DESIGN 6!

Get it here: Official Releases | Ventsim

What’s new?

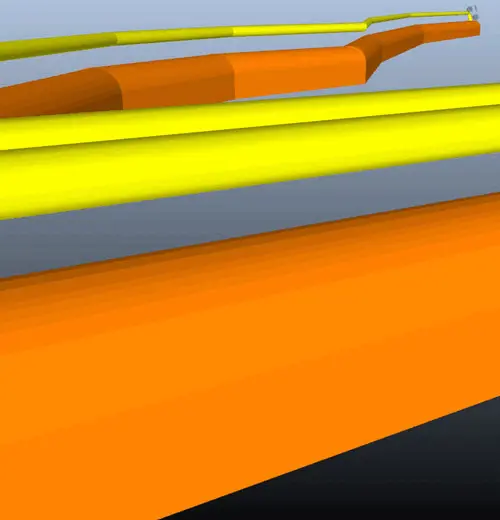

Textured Airways

We have created textures on the airways.

These are not just random visual disturbances, you can customize these to a wide range of pre-configured textures, so they can represent different friction factor presets; you can also scale the texture size based on the friction factor.

Don’t like it? You can toggle it with the button at the top left.

New Improved Error Box

We have revamped the Error Box. Errors and Warnings are now grouped rather than appearing in a long difficult to manage list. This way you can hide errors that occur multiple times and not lose sight of potentially more important but less numerous ones.

To see what airways correspond to each warning you can just click on the group heading and it will cycle the viewer through each. In the example below, if I wanted to see the four airways with stalled fans, I can just click 4 times on “4 stalled fan” heading and I will see each in turn.

I can also click on the check box, and then click Edit to edit the four airways together.

You may have noticed the colours. You can turn that on and off with the colour button at bottom left. This just takes the current colour property on the airway and puts it on the error; so you could colour your errors in the Error Box by, for example, by Air Type, to see which of the errors is occurring in the Return or Fresh Air system.

Battery Fires

You can now model burning Battery Electric Vehicles (BEVs) in your model. In the Fire Wizard, select a battery and then enter its energy capacity. Additionally, Hydrogen Fluoride, a toxic product of battery combustion, can now be modelled as one of the gases in Ventsim

Arrow Colours

Because why not? Get even more information in your viewer by colouring your arrows by Air Type, Primary Layer or Secondary Layer

Customisable Block Button

We’ve improved the Block tool so that you can reconfigure it to apply any of your resistance presets, rather than being forced to apply the 100% block. No excuses for using infinite resistances for your ventilation seals….

Stage Changing

This is a simple one, but a big improvement. Buttons on the main form to quickly move stages

Simplify References

We’ve added a Simplify References tool to the Filter tool. This is a very useful tool for reducing the size and detail on those overly detailed 3D surfaces that you’ve imported into your model.

Restore Cleared Selection

If you’ve ever worked with Ventsim, at some point you’ve made a complicated selection of airways and then lost it, with no way to get it back. No more! Hit Alt-A (or use the new Select menu option) and you’ll have it back

Message Boxes

We’ve reworked the Message Box form, so the Advanced options are always visible and you’ve got more control over when to regenerate the message and data tokens. Also at bottom left you’ve got 2 new buttons. The Copy to Clipbaord will copy the message as well as a whole lot of raw data behind it that you can paste to Excel or wherever to make charts, reports etc. The other button is a shortcut to create a Stage Graph, with which you can plot the variation of the message box data over your stages

(while we’re here, a hot tip: click on an advanced message box with the Zoom cursor and it will shoot the 3D viewer to the associated airway. If there are many airways attached, it will move to a mid point of the airways)

Binding

Binding has been massively sped up. You will only notice this if you commonly use Binding on big models (> 20,000 airways), but if so, it will now be much faster. And you can get another speed up by suspending the Undo

Airway Guides

We’ve improved the Airway Guides to show you the lengths and angles on airways that you’re intercepting with your drawing airway. We’ve also got plans to add something similar for the Add Node cursor.

Carbon Tracker

In the Tools menu, we've added a Carbon Emission Tracker, which makes an estimate of the Scopes 1 and 2 carbon production from the mine; there are also new properties under the Energy category which lets you colour the mine by where the emissions are produced.

Activity Track Creation

Easy ways to create Activity Tracks. Select your path using this tool and this will immediately construct the track for you. Easy.

Dust Profile Simulations

We’ve added the ability to define and simulate dust concentrations over different sizes and densities AT THE SAME TIME. Set a dust profile, press go, and you can see concentrations at various dust sizes throughout your model.

And that’s not even everything.

Thank you for reading and thank you for your suggestions and feedback around the software.

Any problems or comments, please let us know!

-

Hi George. Sorry to hear this. We would like to sort this out.

A couple of options. Can you send us the model you are using that is causing the error? You can send it to ventsim.support@howden.com . Or alternatively, to me via this forum's direct message.

Also, if you are not using version 1.0.0.4539 , then I recommend updating to the latest version via the website download page.

We can also organise a screen sharing session to investigate.

-

Hi Adrian, there is not a clear answer on this. The latent heat factor attempts to account for the evaporation of water around the vehicle, from the airway surfaces, and from any moisture sources on the vehicle. Much the same way as for a diesel vehicle, but without the moisture from the diesel combustion (see McPherson section 15.3.2.2)

If you know the moisture addition from the load and you add it as a separate heat source, then you could turn down the latent heat factor. But not to zero, as the latent heat factor is accounting for other moisture interactions around the vehicle as well.

However, how much moisture exactly you should be adding, as well as where specifically it is coming from, is not known for certain and is an area of interest for us and I imagine many people looking at underground BEV use.

On mine models, this sort of factor (like the rock wetness fraction) is something that can be tuned to match observed dry bulb temperatures.

-

Buenos dias Sebastian,

Disculpas por las problemas. Por favor envianos un correo a ventsim.support@howden.com , quizas con su modelo y investigaremos. Podemos tambien organizar un reunion para investigar mas.

-

Hi Bruno, we might need to get you to show us the problem. Can you email us at ventsim.support@howden.com ?

-

Hi Koray,

I'm not sure. Feel free to send us the model at the support email, or through the forum, and we can take a look.

You can also see the resistance that the fans are working against in the Info box on the fan tab of the Edit Box.

-

Hi Bruno,

What do you mean with the ramp extended?

-

Hi Tonny,

Apologies, I didn't see this thread.

If you have a known flow rate of water from an aquifer entering a mine at a given location, a good place to start is simply with a fixed flow. This is often adequate. There are other options where you can model the amount of water and pressure in the aquifer that are more difficult to set up. Let us know what you are trying to do and we can work it out. Feel free to email us a model at ventsim.support@howden.com

Fixed flows not generating a warning with strict mode enabled

in Ventsim Bug Reports

Posted

This is the best way: